Aquasant Messtechnik AG

Aquasant Messtechnik AG was founded in 1982 with the goal of offeringhigh-quality industrial measuring devices for the chemical industry. A wide range of electro-optical and impedance measuring, monitoring and control unit products are available to meet the increasing need for instruments in the fields of automation and safety.

Mipromex® Fluid Level Measurement

The Mipromex® is not only the supply unit for the measuring point but also the actual intelligence for the evaluation of the impedance measuring signals of pipe or rod probes with on-site measuring electronics MTI. The connection is made via a shielded 2-wire signal cable.

Mipromex® Model MLT 6260

The all-rounder MLT 6260 separation measurement unit processes thedigital measurement signal transmitted by the measurement technology. The intrinsically safe voltage supply to the measurement electronics in the connection head is provided via the signal line. A modern operating and calibration concept with automatic calculation of the measurement range allows for extremely short commissioning of the analog measurement. Measurement signal in mA, percent, or impulse value is displayed, as selected, on the display. An mA analog signal that corresponds to the measurement value and relay output is available as output signals.

- Continuous liquid level measurements

- Impedance measuring principle for bar probes

- Easy calibration via menu-guided commissioning procedure

- Graphic display for the lab with powerful backlighting

- Menu-guided parameterisation D / F / E

- Device data and item no. saving

- Protected parameter entry

- Measurement data processing in microprocessor technology

- One measuring input for MTI probe connection

- Analog output 4-20 mA with galvanized separation, max. strain 750 Ohm

- Monitored measurement circuit from the probe to the relay

- Wire breakage protection and fault monitoring in 4-20 mA mode

- Fault notification can be programmed on the analogue output 0.5 – 4.0 mA / 20.0 – 22.0 mA

- Fault notification display time/date

- Automatic drift compensation

- 2 relay outputs with zero potential switch contact threshold

- mA output and threshold simulation

- RS232-/RS485 interface

- Mains 24 V AC/DC polarity-independent

- ATEX Ex design II (2) G [Ex ia] IIC/ [Exd ia]; SEV 09 ATEX 0132; CE 1254 EMV STS 024 CE

- 19″ tray with aluminum-steel housing; IP 20 height 3 HE; width 12 TE

- Front plate: Height x width 128 x 61 mm / tray: Height x width x depth 100 x 60 x 160 mm

- Typ MLT 6260 IIC V1.1x 24V A/G, Article Nr. 02.32.67.06 xxxx

Mipromex® Model MAT 4140

The analog MAT 4110 measurement unit processes the digital measurement signal transmitted by the measurement technology. The intrinsically safe voltage supply to the measurement electronics in the connection head is provided via the signal line. A modern operating and calibration concept allows for extremely short commissioning of the analog measurement. Measurement signal mA, percent, or impulse value are displayed, as selected, on the display. An mA analog signal that corresponds to the measurement value and relay output is available as output signals. The membrane keyboard with a functional and fully graphic display contributes toward user-friendliness and safe working.

- Separation of water in petrol storage tanks

- Impedance measuring principle for tube and bar probes

- Easy calibration

- Graphic display for the lab with powerful backlighting

- Menu-guided parameterisation D / F / E

- Device data and item no. saving

- Protected parameter entry

- Measurement data processing in microprocessor technology

- One (or two, MAT 4220) measuring inputs for probe connection

- Analog output 4-20 mA with galvanized separation, max. strain 750Ohm

- Monitored measurement circuit from the probe to the relay

- Wire breakage protection and fault monitoring in 4-20 mA mode

- Fault notification can be programmed on the analogue output 0.5 – 4.0 mA / 20.0 – 22.0 mA

- Fault notification display time/date

- Open collector output with zero potential switch contact limit value

- mA output and limit value simulation

- RS232 -/ RS485 interface

- Mains 24 V AC/DC polarity-independent

- ATEX Ex design II (2) G [Ex ia] IIC/ [Exd ia]; SEV 09 ATEX 0132; CE 1254 EMV STS 024 CE

- 19″ tray with aluminum-steel housing; IP 20 height 3 HE; width 12 TE

- Front plate: Height x width 128 x 61 mm / tray: Height x width x depth 100 x 60 x 160 mm

- Typ MAT 4110 IIC V1.1x 24V A/G, Article n°. 02.32.67.01 xxxx

SQV® Tubing Pinch Valve

Dosing in sterile zones, precisely controlled in the feed vessel for pharmaceutical bottling installations, our SQV® is used under sterile conditions in accordance with GMP. They interrupt the flow between the overpressurized and the unpressurized feed vessel without media contact.

The SQV® tubing pinch valves are produced in aluminum or stainless steel as needed and depending on their use. The pneumatically operated Aquasant® valves squeeze the silicone tubing gently enough that at least 10,000 switching cycles with the same hose are possible. Series 1*, 2* and 3*, manufactured from stainless steel, are characterized by an easy-to-use hinged lid.

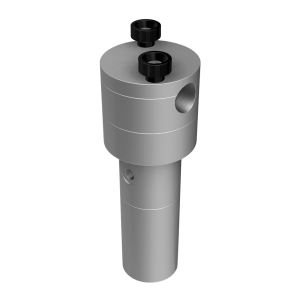

83/15 – SQV®

This reliable third-generation aluminum valve originated from customer needs. The hose squeezing valve’s essential features may be simple, but its high-quality workmanship is impressive.

- Use in sterile zone B

- Easy to handle

- For Silicone tubing Ø 10×15 mm

- Standard: peroxide-cured silicone hoses Shore 60° ±5 (others on request)

- Insertion of hose by loosening two knurled nuts

- Min. 10,000 switching cycles with the same silicone hose, without damage to the hose

- Compressed air supply 4 – 6 bar

- Squeezing stamp in stainless steel

84/20 – SQV®

This reliable third-generation aluminum valve originated from customer needs. The hose squeezing valve’s essential features may be simple, but its high-quality workmanship is impressive.

- Use in sterile zone B

- Easy to handle

- For Silicone hose Ø 15×20 mm

- Standard: peroxide-cured silicone hoses Shore 60° ±5 (others on request)

- Insertion of hose by loosening two knurled nuts

- Min. 10,000 switching cycles with the same silicone hose, without damage to the hose

- Compressed air supply 4 – 6 bar

- Squeezing stamp in stainless steel

96/2×11 MV – SQV®

A double valve as changeover. Based on new demand, the tried-and-tested aluminum valve, in various nominal diameters, was further developed as a shuttle valve. With its essential features remaining the same, the new valve can be controlled with an electro-pneumatic magnet valve in 24 V or 230 V.

- Shuttle valve on each side NC/NO

- Use in sterile zone B

- Easy to handle

- For Silicone tubing Ø 5×15 mm

- Standard: peroxide-cured silicone tubing Shore 60° ±5 (others on request)

- Insertion of the tube by loosening two knurled nuts

- Min. 10,000 switching cycles with same silicone tubing, without damage to the hose

- Compressed air supply 4 – 6 bar

- Squeezing stamp in stainless steel

1* G1/8 VAe N KV- SQV®

The Phönix. The reliable SQV® was redesigned and optimized for sterile zone A. Thanks to a refined hinged lid system, the SQV® VK version makes inserting the hose into the insulator with gloves a much more user-friendly process.

- Use in sterile zone A/B

- Easy to handle in the insulator

- For silicone tubing dimensions 6-16 mm

- Standard: peroxide-cured silicone tubing Shore 60° ±5 (others on request)

- Insertion of hose by loosening large polygon screw-on hinged lid

- Min. 10,000 switching cycles with same silicone tube, without damage to the tube

- Compressed air supply 4 – 6 bar

- Housing IP 53 stainless steel 316L, RA 0.8, electropolished

2* G1/8 VAe N KV – SQV®

- Use in sterile zone A/B

- Easy to handle in the insulator

- For silicone tubing dimensions 17-20 mm

- Standard: peroxide-cured silicone tubing Shore 60° ±5 (others on request)

- Insertion of hose by loosening large polygon screw-on hinged lid

- Min. 10,000 switching cycles with same silicone tube, without damage to the tube

- Compressed air supply 4 – 6 bar

- Housing IP 53 stainless steel 316L, RA 0.8, electropolished

3* G1/8 VAe N KV – SQV®

- Use in sterile zone A/B

- Easy to handle in the insulator

- For silicone tubing dimensions 17-20 mm

- Standard: peroxide-cured silicone tubing Shore 60° ±5 (others on request)

- Insertion of hose by loosening large polygon screw-on hinged lid

- Min. 10,000 switching cycles with same silicone tube, without damage to the tube

- Compressed air supply 4 – 6 bar

- Housing IP 53 stainless steel 316L, RA 0.8, electropolished

4* G1/8 VAe N KV – SQV®

- Use in sterile zone A/B

- Easy to handle in the insulator

- For silicone tubing dimensions 17-20 mm

- Standard: peroxide-cured silicone tubing Shore 60° ±5 (others on request)

- Insertion of hose by loosening large polygon screw-on hinged lid

- Min. 10,000 switching cycles with same silicone tube, without damage to the tube

- Compressed air supply 4 – 6 bar

- Housing IP 53 stainless steel 316L, RA 0.8, electropolished

Turbymex® Turbidity Measurement Systems

The turbidity measurement system is used in the chemical, pharmaceutical, biotechnology, food, and petrochemical industries. The in-situ sensor measures on one level based on the reflection principle.

Turbymex® – the turbidity meter The system measures the crystallization and cell density increase or monitors the filtration process or condensate The ATM100 allows a 6-point linearisation per channel. Up to four measuring points can be operated via the bus. From sensors in 316L stainless steel with a fibre optic cable and remote local coupler electronics to mounted versions in various nominal sizes, almost anything is possible. The sum signal is high-resolution and sensitive due to the optical receiver lens.

ATM100

The evaluation electronics not only serve as a feed unit to the 4-wire bus but also house the data processing intelligence in a secure manner with dynamic monitoring. All four measuring inputs have the same functionality. The benefit for you: high economic efficiency and investment security due to the long service life.

- Each of them has an analog output of 4 – 20 mA with galvanic isolation

- Each of them has 2 limit value relay outputs

- 1 to 4 measuring inputs via the bus for ATA100 sensor connection

- 6 linearisation points

- Data logger with Excel export function

- Ethernet web application

AF44 | Gv ATA*

The AF44 fiber optic sensors are NEW and available with compact and mounted ATA100 coupler electronics in stainless aluminum or steel housing.

- Mounted connection head with ATA100* and/or with a cooling element, product temperatures up to 120°C

- Materialization: Stainless steel, Hastelloy®, PP designs

- Sensor shaft lengths, the position of O-ring groove standardized or customer-specific

- Process connection Ø 25 mm with G11/4″ union nut

- Connection head for aluminum powder-coated IP65 or stainless steel IP68