Mounting of a Vibration Sensor

Mounting of a vibration sensor is affect to the sensor’s operating performance directly. Specifically wrong or poor mounting, can cause inaccurate outputs. It also causes unstable sensor operating which is eventually causes critical system faults. Therefore, mounting process is critical for getting reliable and accurate outputs. Mounting of vibration sensors on specific parts of the machines provide users to detect errors in the machine components.

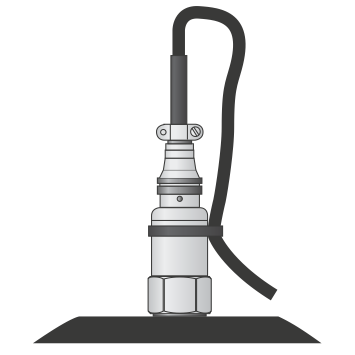

For Vertical Measurement

Vibration sensor should be placed on bearing motor and pump parts. In this connection type, vibration sensor measures machine faults and general system looses. The sensor measures the velocity in mm/sec (Peak or RMS) for this process.

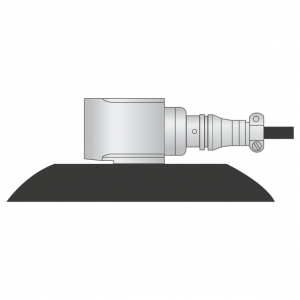

For Horizontal Measurement

Vibration transmitter should be mounted on motor and pump parts. This mounting type uses for detect misalignments and structural defects of the machine. The sensor measures the velocity in mm/sec (Peak or RMS) for detecting potential faults.

For Axial Measurement

Accelerometer should be mounted at motor and pump parts of the machine. With this mounting type, the sensor measures the velocity in mm/s (Peak or RMS). The operation in here, vibration sensor measures the misalignment between motor and fan parts.

Vibration analyst should mount accelerometers (velocity sensors) on the pure, smooth surfaces. Besides, place the vibration sensors as close as possible to the vibration source. The surface must be smooth, unpainted, flat, and wider than the vibration sensor’s mounting part. For getting the best result, mount vibration sensors directly to the machine body with a drilled and screwed hole of the machine body.

If you want to look our Hansford Sensors products, click here.